- Product Information

- Specifications

- Product Image

- Production Video

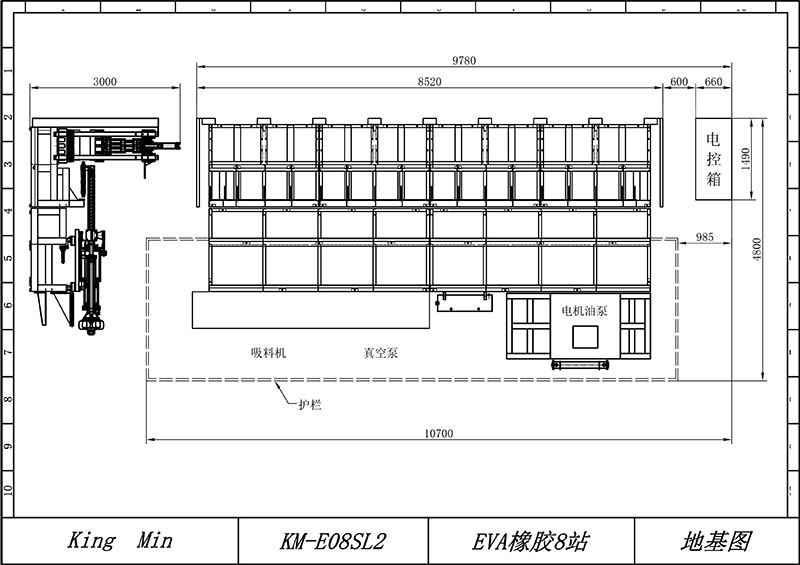

- Foundation Plans

-

1. Control System : Utilized industrial workstation computer in windows control system applying picture type of operation with touch screen to monitor the screw turning speed , injection volume time , injection temperature , mould temperature, movement time and productivity on line, easy to learn and operate.

2. Injection System: The measuring mechanism utilizes potentiometer detection and coordinates with the operation of PLC to control material volume precisely. Driven by linear track, it allows to move speedy and position precisely.

3. Mold Clamping System : Act by toggle mechanism, it opens the mould rapidly. The two-step speedy mould opening/closing mechanism is with detecting device of fully mould closing. Low operation height, high mould opening stroke, can apply to various styles of moulds flexibly. Equipped with hydraulic cylinder, it allows 2mm thickness difference between 2 moulds on one mould station. By fixed mould opening stroke 350mm,it is not affected by any mould thickness changes.

4. Hydraulic System : Reducing noise and upgrading efficiency by applying 3 sets of pump work individually. Precisely control the pressure and flow rate by using proportional valve and computer system.

5. Accessories : No need to water circulation for mould station, using efficient heat insulation material.

6. Equipped with special screw, it is available for rubber and EVA material

-

Full Automatic Foam EVA/RB Special Injection Moulding Machine

项目

ITEM

UNIT

KM-E04SL2

KM-E06SL2

KM-E08SL2

使用原料

Material

EVA/RUBBER

工作站數

Work Stations

stations

4

6

8

合模力

Mold Clamping Force

kg

240000

240000

240000

開模行程

Mold Opening Stroke

mm

400

400

400

模板尺寸

Mold size(mm)

mm

330*600*2set

330*600*2set

330*600*2set

標準模厚

Standard Mold Thickness

mm

100-350

100-350

100-350

電熱容量

Heating Power of Mold

kw

12

12

12

螺桿直徑

Screw Diameter

mm

65/70/75

65/70/75

65/70/75

******射出量

Max.Injecting Capacity

cc

1150/1340/1540

1150/1340/1540

1150/1340/1540

射出壓力

Injecting Pressure

kg/cm2

1200

1200

1200

射出速度

Injection Speed

cm/sec

10

10

10

螺桿轉速

Rotating Speed of Screw

r.p.m.

0-120

0-120

0-120

料管電熱能量

Heating Power of Barrel

kw

14.1

14.1

14.1

模具加熱板

Heating Power of Mold Plate

kw

73.6

110.4

147.2

伺服電機

Electricity

kw

66

66

66

總用電量

Total Electricity Consumption

kw

153.7

190.5

227.3

用油量

Using Amount of Oi

L

800

800

800

機器尺寸

Machine Dimension L*W*H

mm

6565*5000*3040

8575*5000*3040

10585*5000*3040

機器重量

Machine Weight

kg

20000

28000

36000

-

-

-